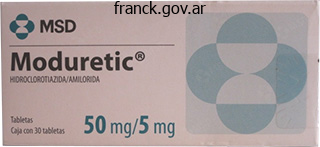

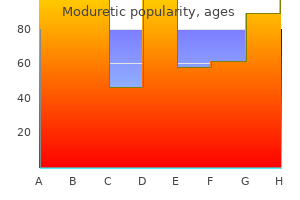

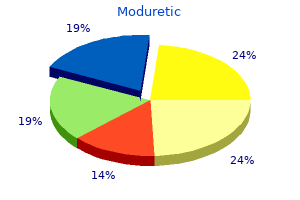

Moduretic dosages: 50 mg, 50 mg

Moduretic packs: 60 pills, 90 pills, 120 pills, 180 pills, 270 pills, 360 pills

Moduretic 50 mg order mastercard

The following are thoughts for consideration to implement change to a lifecycle strategy: 1. Validation approval committee: Members of the positioning validation approval committee should additionally lend a hand with your proposal. Training: After approvals to course of are obtained from greater operations and Quality Systems management, a number of groups should be trained on the lifecycle method: � Development group should be educated on Stage 1 actions. Evaluations will be influenced by kind (potency) of drug in facility, drug complexity, single or multiproduct facility, level of guide cleansing, and different concerns. Depending on the scenario, deficiencies in any of the next could presumably be very serious issues. Summary the lifecycle approach to cleaning validation is a logical strategy for cleaning and cleansing validation programs. As organizations implement the lifecycle method for manufacturing processes, equipment, utilities, controls, and other techniques, software to cleaning validation should even be thought-about. Implementation of the lifecycle method addresses a quantity of essential points for cleaning and cleansing validation. Development of cleansing processes have to be based on scientific and technical principles. Once developed utilizing this approach, cleaning is handled as a dependable and reproducible course of and never as a essential evil or an activity that requires doing "whatever it takes" to clean gear. Finally, reliability of the cleansing process is maintained via a monitoring course of that features change management and management. Implementation of the lifecycle strategy for cleaning will probably require a major paradigm shift within the group. These include the technical perform that has carried out the development work, including writers of technical documentation, efficiency perform, the doc review/approval perform (site validation approval committee), quality operate liable for ongoing compliance, and the validation perform. The lifecycle method enables cleansing to be addressed in the identical method as all different critical technical processes, gear, and systems at the manufacturing site. Recommendations on Validation Master Plan, Installation and Operational Qualification, Non-Sterile Process Validation, Cleaning Validation. In situ monitoring of soil dissolution dynamics: A fast and easy methodology for determining worst-case soils for cleansing validation. Standard Guide for Specification, Design, and Verification of Pharmaceutical and Biopharmaceutical Manufacturing Systems and Equipment. Development and Manufacture of Drug Substances (chemical entities and biotechnological/biological entities). Freeze-drying is most necessary in the production of injectable prescribed drugs, and in addition finds software in the manufacture of diagnostics and in certain 907 908 stable oral dosage varieties the place fast disintegration and dissolution is important. In addition to permitting removal of water at low temperature, freeze-drying beneath acceptable conditions usually ends in a stable material with a relatively excessive particular floor space, which facilitates rapid, complete dissolution. This is a critical high quality attribute for medicine administered in emergency conditions. Finally, freeze-drying is extra appropriate with sterile operations than filling a stable powder into vials. The solution may be sterile filtered instantly earlier than filling, and fill weights of liquids dispensed into the primary container can be extra persistently controlled than filling of dry powders. Filling of a solution into vials additionally avoids potential issues with cross contamination through airborne particulate matter, as nicely as publicity of workers to probably hazardous medicine. The software of freeze-drying to manufacture of injectable merchandise has continued to grow, notably with the appearance of biotechnology-based therapeutics. According to 2016 gross sales knowledge, of the 5 largest promoting drug merchandise on the earth, 4 are therapeutic proteins and, of those four, two can be found as a freeze-dried solid in a vial (1). This is a testament not only to the dominant position of proteins as therapeutic brokers but also to the crucial nature of freeze-drying within the manufacture of those medicine. Freeze-drying takes place due to sublimation, where water converts from the solid state to the vapor state without first turning into a liquid. This can only occur below the triple level of ice, which is at a temperature of about 0�C and a pressure of about four. This pressure refers to the partial pressure of water vapor, not the entire system stress, so sublimation of ice can happen at atmospheric stress as long as the partial stress of water vapor is less than about four. Everyday examples of sublimation of ice include ice cubes shrinking over time in the home freezer, in addition to "freezer burn" brought on by local sublimation in frozen food products. In order to be a practical process commercially, the system strain should be maintained below the vapor stress of ice, in order that the water vapor is transported by bulk vapor flow from a region of high strain (the ice surface) to a decrease pressure maintained in the freeze-dry chamber by the use of a condenser maintained at a temperature within the range of -60�C to -80�C.

Purchase moduretic online

However, as a result of the impulse in a single pathway is touring extra slowly than normal, by the time it circles around and travels upward along the opposite pathway, enough time has passed so the pathway is no longer in its absolute refractory period, and now the impulse could travel upward in that pathway. In different words, the electrical impulse "reenters" a beforehand stimulated pathway in the reverse (retrograde) path. There are two pathways for impulse conduction, slowed impulse conduction down pathway A and an extended refractory interval in pathway B. However, due to dispersion of refractoriness (ie, different refractory intervals down the two pathways), the impulse could be carried out down pathway A. Because conduction down pathway A is slowed, by the point the impulse reaches pathway B in a retrograde path, the impulse could be carried out retrogradely up the pathway because the pathway is now beyond its refractory interval from the earlier impulse. This creates reentry, in which the impulse constantly and repeatedly travels in a round trend across the loop. The modified Vaughan Williams classification of antiarrhythmic drugs is offered in Table 9�1. The Vaughan Williams classification of antiarrhythmic medicine has notable limitations. The classification is based on the consequences of medication on normal, rather than diseased, myocardium. Amiodarone inhibits sodium and potassium conductance, is a noncompetitive inhibitor of -receptors, and inhibits calcium channels, and subsequently may be positioned into any of the four courses. Nonetheless, regardless of attempts to develop mechanism-based classifications that higher distinguish the actions of antiarrhythmic medication, the Vaughan Williams classification continues to be widely used due to its simplicity. In ventricular tissue only; results could differ in atria, sinus node, or atrioventricular node. In the absence of correctable underlying causes, idiopathic sinus node dysfunction is referred to as sick sinus syndrome. The prevalence of sick L O 3 sinus syndrome is roughly 1 in 600 people older than sixty five years, whereas the incidence is about zero. However, there are different attainable etiologies of sinus bradycardia together with drugs (Table 9�2). Treatment of sinus Pharmacologic Therapy bradycardia is only needed in patients who turn out to be symptomatic. If the affected person is taking any medication(s) that may trigger symptomatic sinus bradycardia, they need to be discontinued each time possible. If the affected person remains in sinus bradycardia after drug discontinuation and after five half-lives of the drug(s) have elapsed, then drug(s) can often be excluded as the etiology. In certain circumstances, nevertheless, discontinuation could additionally be undesirable, even if the drug may be the cause for symptomatic sinus bradycardia. In this example, clinicians and sufferers could elect to implant a everlasting pacemaker to permit continuation of therapy with -blockers. Acute therapy of the symptomatic and/or hemodynamically unstable patient with sinus bradycardia includes administration of the anticholinergic drug atropine, which must be given in doses of zero. Where essential, transcutaneous pacing could be initiated throughout atropine administration. In sufferers with hemodynamically unstable sinus bradycardia unresponsive to atropine, transcutaneous pacing may be initiated. Nonpharmacologic Therapy Long-term administration of patients with sick sinus syndrome requires implantation of a permanent pacemaker. In these patients, clinicians and sufferers may elect to implant a permanent pacemaker to permit the patient to proceed -blocker therapy. He states that this began several hours ago, and he waited to see if it might cease, but it has not. The thrombus then could travel through a carotid artery into the brain, resulting in an ischemic stroke. This is most likely going as a result of activation of the sympathetic nervous system during exercise and exercise overwhelms the stimulating impact of digoxin on the parasympathetic nervous system. Diltiazem could additionally be preferable to verapamil in older patients as a end result of a lower incidence of constipation. Fortunately, research have found the combination of digoxin and -blockers to be effective for ventricular rate management, likely as a end result of -blocker�induced attenuation of the inhibitory effects of the sympathetic nervous system on the efficacy of digoxin. What pharmacologic or nonpharmacologic alternate options are available for every treatment objective

Generic 50 mg moduretic amex

The Compendial Sterility Tests One frequently ignored facet of discussions of sampling plans is that the statistical analyses assume that the check system would get well even a single microorganism if it had been current within the sample. These media and their corresponding incubation temperatures had been chosen to maximize recovery of potential contaminants early in the development of the exams. However, some authors have questioned the choice of media [6], while others have suggested that the utilization of stable media rather than liquid media could be appropriate [7]. The choices within the current harmonized procedure mirror those media to which all events within the harmonization process might agree. Similarly, the Pharm Eur 3rd Edition [11] allowed a 7-day incubation interval (unless mandated otherwise by local authorities). This allowance was amended in 1998 with the 4th edition to 14 days incubation [12]. More just lately, this place was repeated with retrospective knowledge offered by German and Australian workers who wished to make certain that a harmonized process included an incubation interval of no much less than 14 days [14,15]. Equipment Commonly Used for the Sterility Tests Traditionally, the sterility check has been carried out in a clear room maintained on the equal of grade "B" situations using an enclosure such as a horizontal laminar airflow cabinet that meets grade "A" conditions to minimize the potential for false positives. The consideration right here is that incubators used within the microbiology laboratory generally include either petri dishes or liquid cultures that help excessive numbers of bacterial cells. The use of this identical incubator for sterility testing is chancy at finest, and if the situation arose, the investigation of a sterility check constructive outcome would turn out to be hopelessly confounded by the untestable suspicion that the test became contaminated in the incubator. It is a lot better to minimize any potential for laboratory contamination-in this instance via the utilization of devoted incubators for the sterility take a look at recovery media incubation. The anathema of a false sterility optimistic drives many equipment and procedural decisions in the sterility exams. Several specialised items of apparatus have been developed for the membrane filtration sterility test with the aim in thoughts of minimizing the potential for adventitious contamination of the check. This system (and others like it) offers one other barrier level to adventitious contamination of the sterility take a look at pattern. When coupled with use of a take a look at isolator system, the possibilities of false positives within the test turn out to be vanishingly small (see the section under on Investigations). Now, a retest is only allowed if the original test was found to be contaminated on account of a defective technique or the use of faulty supplies, thus invalidating the unique test. Common practice is to use 10 mL of bulk product/media (for a complete of 20 mL) for this testing. This informational chapter offers background in isolator design and development, the equipment qualification issues for the isolator, validation of the decontamination cycle (this would include the inner surroundings, the exterior of the product containers entering for testing, and the safety of the product from the decontamination cycle), and the upkeep of asepsis inside the isolator surroundings. The reader is also instructed that a sterility check carried out in a properly functioning isolator could be very unlikely to end in a false optimistic end result. This could also be true for environmental circumstances; nonetheless, this will not be the case if defective materials, for instance, non-sterile media or rinse fluids are used. Finally, instruction is offered on the training and safety elements of the isolator operation. On a final notice in regard to gear, given the laws surrounding the test (see below) and the extreme incentives to avoid false optimistic results, the consumer is cautioned to undertake new expertise solely after cautious deliberation for this explicit utility. Clarifications and Enhancements to the Harmonized Sterility Tests There have been quite a couple of clarifications provided by totally different regulatory companies to the compendial sterility exams. We will, however, take a look at a couple of of the clarifications provided by totally different regulatory agencies on the implementation of the harmonized check. The user is instructed that the check can be performed in a Class A laminar airflow cabinet located in a Class B room or an isolator. Finally, elaboration is offered on "Observation and Interpretation of Results" in that during an investigation. There used to be several variations within the take a look at from the internationally harmonized checks that embrace controls, technique suitability requirements, the Compendial Sterility Tests materials and/or the testing setting. The authors are unaware of this apply outside this doc in common utilization for the pharmaceutical trade.

Moduretic 50 mg free shipping

Magnesium concentrations need to be Because magnesium monitored carefully in these sufferers. Mild hypermagnesemia is current if the serum magnesium concentration is between 2. Severe hypermagnesemia is current if the serum magnesium focus is greater than 13 mEq/L (6. Mild hypermagnesemia and average hypermagnesemia without cardiac findings may be handled with normal saline infusion and furosemide therapy (assuming the patient has normal renal function). L O 6 dietary supplements, and the bisphosphonates (eg, pamidronate, varied manufacturers). Dietary restriction of phosphate and protein is effective for most minor elevations. Phosphate binders corresponding to aluminum-based antacids, calcium carbonate, calcium acetate (PhosLo, obtainable as generic), sevelamer hydrochloride (Renagel, Genzyme), sevelamer carbonate (Renvela, Genzyme, Global), and lanthanum carbonate (Fosrenol, Shire) may be needed for some sufferers (typically those with continual renal failure). Magnesium catalyzes and/ or activates more than 300 enzymes, offers neuromuscular stability, and is involved in myocardial contraction. Magnesium is generally not a part of commonplace chemistry panels and due to this fact must be ordered individually. Clinicians should consider the magnesium focus in these sufferers and proper if low. To consider magnesium status, both laboratory exams and scientific evaluation are required. In order for calcium and potassium concentrations to normalize, magnesium supplementation is often required. Medications that probably may cause hypomagnesemia embody aminoglycoside antibiotics, amphotericin B (available as generic), cisplatin (available as generic), insulin, cyclosporine (available as generic), loop diuretics, and thiazide diuretics. Similarly, disturbances in serum sodium, potassium, calcium, phosphorus, and magnesium are ubiquitous and must be mastered by all clinicians. Dysregulation of fluid and/or electrolyte status has critical implications relating to the concepts of drug absorption, volumes of distribution, and toxicity. Similarly, many drugs can disrupt fluid and/or electrolyte stability as an unintended consequence. What are the doubtless causes for the elevated sodium concentration in this patient Using the equation (1500 mL + 20 mL for every kilogram > 20 kg), calculate the rate of fluid administration for the entire fluids needed in this 24-hour interval and over the following 48 hours. Common fluid� electrolyte and acid�base problems in the intensive care unit: chosen issues. The Albumin Reviewers (Alderson P, Bunn F, Lefebvre C, Li Wan Po A, Li L, Roberts I, Schlerhout G. A new graduated routine for phosphorous alternative in sufferers receiving nutritional help. Effect of hypophosphatemia on diaphragmatic contractility in sufferers with acute respiratory failure. Efficacy and security of intravenous phosphate substitute in critically sick patients. Fluids and Electrolytes with Clinical Applications: A Programmed Approach, seventh ed. The therapeutic use of magnesium in anesthesiology, intensive care and emergency drugs: a evaluation. Efficacy and security of potassium infusion therapy in hypokalemic critically unwell patients. Rapid correction of hypokalemia utilizing concentrated intravenous potassium chloride infusions. Compare and contrast the four major acid�base disturbances within the human body. Apply easy formulation in a scientific method to determine the etiology of easy acid�base disturbances and the adequacy of compensation.

Buy moduretic 50 mg with mastercard

Perhaps the most important supply of uncertainty in the utilization of a freeze-drying microscope is the uncertainty round determination of a collapse temperature. Some formulations endure collapse somewhat abruptly as the temperature of the system is increased. The most relevant data is the extent of collapse that can be detected visually within the freezedried solids. However, the extent of microscopic collapse that might correspond to visually observable collapse may not be obvious. Heat and mass transfer in freeze-drying are associated by way of the warmth of sublimation of ice, Hs, which is about 2,803 J/g. Heat and mass transfer, like all switch operations, follow the overall type of Flux (or move rate) = driving drive � conductance Alternatively, the move time period could be expressed as a driving pressure divided by a resistance. For warmth transfer, the flow fee time period refers to the rate of warmth transfer, the driving drive is a temperature difference, and the conductance time period might be the thermal conductivity of a material, similar to ice. For mass switch, the circulate price term is the sublimation rate, the driving force is a stress distinction, and conductance term is mostly expressed as a resistance to mass transfer. Complications come up, though, as a result of freeze-drying takes place in a system at low stress, and the transport properties of the vapor are a perform of the system pressure. The maximum rate of evaporation (or sublimation) is a operate of the vapor strain of the substance at a given temperature, as properly as the molecular weight of the material. Using appropriate values for water, and assuming 2 mm of water in a vial, leads to the conclusion that, if the ice were allowed to chic at its maximum rate, the ice can be removed in about 1 min. Why, then, does it take 2 days A basic property of gases at low stress as regards transport properties of gases is the Knudsen quantity, or Kn, which is the ratio of the molecular imply free path, L, to a characteristic dimension of the system, a. For water vapor, the mean free path is roughly L (cm) = 3 PmT the place the pressure, PmT, is expressed in milliTorr (mT). For instance, at 50 mT, which is representative of pressures used in freeze-drying, the imply free path of water vapor is about 0. For example, if the difficulty is move of vapor through the pores of the partially dried solids, a is the common diameter of the pores in the cake. In this case, the value of a is the typical thickness of the "gap" between the bottom of the vial and the shelf. If the difficulty is circulate of vapor by way of the duct connecting the chamber of the freeze dryer with the condenser, a could be the diameter of the duct. When the mean free path is small compared to the attribute dimension a, collisions between fuel molecules are rather more frequent than collisions with the boundaries of the system under consideration. Since collisions between molecules decide the viscosity of the gasoline, this move regime known as viscous flow. A third flow regime is transition move, which lies between viscous and Knudsen circulate. Approximate values of Kn delineating the completely different move regimes are as follows: Kn < 0. Knudsen developed the theory of thermal conductance of gases on this circulate regime based mostly on collisions of individual molecules with a floor. As discussed above, the fuel conduct on this range is set by collisions of molecules with the boundaries of a system, not on collisions between gasoline molecules. When a molecule at a temperature Ti strikes a floor at a higher temperature Ts, the incident molecule picks up thermal energy from the collision. The extent to which the power is elevated by the collision is expressed by a time period known as the lodging coefficient, the place Consider, as an example, steady-state warmth transfer between two parallel plates separated by a distance x of 0. One millimeter would be roughly the efficient separation distance resulting from the underside of glass vials not being flat. First think about a system under vacuum containing only water vapor at a strain of 1,000 mT, where the molecular imply free path is 0. Of course, precise freeze-drying takes place at pressures intermediate between these pressures, so the conductive heat switch consists of components of each viscous move and free molecular flow, however the viscous flow component would tend to dominate over the free molecular element. If = 1, then the trade of power is complete, and the molecule acquires the temperature of the warmer surface after one collision. Using the kinetic principle of gases, it could be proven that the rate of energy transfer from a sizzling surface to a chilly floor per unit area is Eo = o P 273 Ti 1/ 2 (Ts - Ti) Note that, within the free molecular move regime, the rate of power transfer is instantly associated to the system pressure. Note that the conductance of water vapor is considerably larger than that of air. Note also that the speed of vitality switch is independent of the distance separating the our bodies exchanging warmth.

Buy moduretic pills in toronto

These include time, motion, concentration, temperature, surface sort and quality, soil stage, soil condition, mixing, water quality, rinsing, and environmental factors. The chemistry of the cleansing course of and its effect on the residue should be recognized to develop an acceptable analytical technique for residue determination. After preliminary design and laboratory-scale growth work is completed, the cleaning course of is examined on prototype equipment, scaled up, and finally transferred to the actual business manufacturing site. Modifications within the course of may be necessary primarily based on obtainable gear and different concerns. Analytical strategies utilized in cleansing technique design and development must be technically sound. Data generated are used to make key choices with important impact on cleaning validation. Analytical strategies could also be validated as early as potential in Stage 1 and can ultimately be formally validated when needed to be used in Stage 2 cleansing validation. Residue Determination Analytical dedication of product residue is prime to cleansing validation. When the cleaning process offers equipment surfaces with residue levels below that which 886 is set to be secure, the cleansing course of is successful. Scientists who develop the analytical methodology for cleaning validation should understand the composition of the residue in order that acceptable analytical strategies are developed. The analytical methodology used must be acceptable for the actual residue present on tools. Nonuniform contamination areas have the potential for excessively highresidue carryover. Recovery Studies Quantitative recovery of analyte from equipment surfaces is a key requirement for acceptable analytical methods. Product Residue Considerations the character and properties of the product residue to be cleaned are of vital significance to the cleaning course of. The properties of the residue to be cleaned must be the primary consideration in cleaning course of improvement. Comparison of a product manufacturing process and a soil cleansing course of demonstrates the importance of understanding soil properties. In a product manufacturing course of, drug and inactive elements are processed to yield a last dosage type. The properties of the drug and excipients are critical to creating an appropriate manufacturing process that can yield a stable and efficacious product-material properties are key. Equipment contaminated with product residue is processed with cleaning agent(s) to yield a clean gear floor. The properties of the soil and the cleaning agent are critical to developing an acceptable cleaning course of that may yield clear gear surfaces. Three matters involving product residue are mentioned: � Physical and chemical properties of residue as a basis for cleaning. Examples of optimized cleansing procedures based mostly on residue solubility are introduced. Correct dedication of the most-difficult-toclean product in a matrix is a crucial determination for a cleaning validation program. However, residue cleanability is essential and may not be adequately thought-about. Residue cleanability could also be very considerably influenced by inactive ingredients within the residue. Sampling Sampling of apparatus surfaces for quantitative analysis is a key exercise in cleansing validation. Sampling methods should be clearly specified as a half of the analytical methodology for the analyte. The work carried out during Stage 1 of the lifecycle method to cleaning and cleansing validation is prime to the long run success of the cleaning program. Activities initiated in Stage 1 provide the technical foundation for future Stage 2, Stage three, and course of improvements in cleansing. Fundamental work conducted in Stage 1, similar to drug solubility, drug degradation, and related research, may be referenced long after initial cleaning studies as the basis for varied cleaning process changes and enhancements. Despite the fundamental nature of Stage 1 work, organizations could overlook or decrease work in certain areas. Significant Stage 1 issues identified by cleansing validation practitioners embrace the following: � Product residue concerns: these include physical and chemical properties of residues as a basis for cleaning, residue solubility in most-difficult-to-clean residue matrix, and assessing cleanability in figuring out the most-difficult-to-clean residue.

Buy generic moduretic 50 mg online

At a certain crucial salt stage, cation channels open up in the membrane permitting an trade of ions to happen. Increase in the intracellular salt focus also causes a salting-in of the cytoplasmic proteins. Salting-in permits the free ions within the intracellular resolution to start to interact with the now solubilized protein, which reduces the focus of free ions and attracts in additional ions from the extracellular space. Densely packed cells are more probably to be damaged by mechanical stresses throughout the ice channels. Upon thawing, the ice melts and dilutes the extracellular solution back to isotonic. Higher osmotic strain contained in the cell causes water to enter the cell and dilute the salt in the cytoplasm. When both the intracellular and extracellular salt concentrations have gone under the crucial stage, the cation channels in the membrane shut as quickly as once more. In parallel, lowering of the intracellular salt concentration causes cytoplasmic proteins to be salt-out once more. This releases the corresponding sure ions, leading to a larger 967 number of ions being trapped contained in the cell than have been there initially. A higher amount of water due to this fact enters the cell causing the volume of the cell to broaden past its isotonic initial volume. If the cell expands previous a crucial yield quantity, the membrane will rupture causing cell lysis [117]. The sort and extent of injury during cooling is also dependent on the cooling (processing) fee. With sluggish cooling, hypothermic harm as properly as osmotic injury turns into important, as a end result of the longer process time. Cells are additionally exposed to the cryoconcentrated solutes for a longer time frame (including to any added cryoprotectants) in the hypothermic zone resulting in toxic "resolution results. The greater the degree of extracellular supercooling, the lower the ice nucleation temperature, and the greater is the incidence of intracellular ice formation. Intracellular ice harm is seen as cell rupture and speedy necrosis (~0�6 h) after thaw [116,118,121�126]. A abstract of stress factors in hypothermic storage and cryopreservation is provided in Table forty four. Cross discuss between apoptopic and necrotic cascades can result in secondary necrosis leading to low viability post-thaw. Energy deprivation can initiate apoptosis, however extreme vitality deprivation may cause a transition from initial apoptosis to secondary necrosis [116]. Cryopreservation answer should enable upkeep of ionic ratios, good pH control (through addition of acceptable buffering reagents), scavenging of free radicals, maintenance of oncotic balance, in addition to a provide of vitality substitutes. Apart from these mobile stresses, the bodily stresses of osmosis and ice formation have to be addressed. In addition to an answer medium corresponding to above, which preserves within the hypothermic zone, (during hypothermic storage, pre- and post-thaw), an additional protectant is required for the freezing stage to tackle the bodily stresses of cryopreservation. There is a diverse range of compounds that have been recognized and embrace membrane penetrating and non-penetrating brokers. Penetrating brokers are usually efficient in minimizing damage in slow-freezing systems. These agents function by dehydrating the cells previous to freezing and by forming hydrogen bonds with water to reduce water exercise in the frozen state. These brokers are effective at defending cells in high cooling price systems [117,124,131,132]. When cryoprotectants are added in sufficiently giant amounts (with respect to the quantity to be frozen) and cooled at a rapid rate, the formation of ice could be prevented. Once cooled to under the Tg, the cells are successfully preserved on this now vitrified matrix. Low cryoprotectant concentrations require very excessive cooling charges (10�C/min�100�C/min).

50 mg moduretic mastercard

At a sure strain stage, liquid shall be pressured first from the set of largest pores, in preserving with the inverse relationship of the utilized air pressure P and the diameter of the pore, d, described within the bubble point equation: where is the surface tension of the fluid, is the wetting angle, P is the upstream strain at which the most important pore will be freed of liquid, and d is the diameter of the largest pore. When the wetting fluid is expelled from the biggest pore, a bulk gas flow might be evaluated on the downstream side of the filter system during a handbook check. Therefore, filter manufacturers specify the bubble level limits as the minimal allowable bubble level and correlate the bubble level check process to the bacteria challenge take a look at. During the integrity check, the bubble level take a look at has to exceed the set minimum bubble point for it to cross. Key for a successful bubble point take a look at is the qualified wetting fluid and its surface rigidity. The bubble level might be extremely influenced by surface rigidity adjustments inside the wetting fluid. The floor rigidity of the wetting liquid and its viscosity diminish with rising temperature, whereas the angle of wetting increases and its cosine decreases with the hydrophobicity of the filter polymer. The less hydrophilic the polymer, the much less completely does it wet, notably with aqueous liquids. Therefore, the bubble point is a selected product of the each explicit filter/ liquid couple. That the bubble level of a filter differs for various wetting liquids is commonly identified. The larger the filter floor, the larger the influence of the diffusive flow by way of the membrane. Therefore, the bubble point finds its best use with very small systems to medium-size techniques (some mention the important borderline to use the bubble level is a three � 20 filter housing, depending on the pore size). Filters and Filtration 773 strain, and is the void volume of the membrane, its membrane porosity, generally round 80%. The size of pores does only enter not directly into the equation; in their mixture, they comprise L, the thickness of the liquid layer, the membrane being some 80% porous. Therefore, a flaw or an outsized pore would be measured by the thinning of the liquid layer due to the elevated take a look at stress on the upstream facet. The pore or defect is probably not giant sufficient that the bubble point comes into impact, but the check stress thins the liquid layer enough to result into an elevated gasoline move. Therefore, filter producers specify the diffusive circulate integrity check limits as most allowable diffusion worth. The test time would be far too extensive and the measured check worth too unreliable to be utilized. Nevertheless, the diffusive flow and the stress drop exams are greatest used for bigger filtration surfaces where the bubble point test finds its limitations (50). The take a look at setup is organized as within the diffusion test besides that when the stipulated utilized strain is reached, the stress source is valved off. The decay of stress inside the holder is then observed as a operate of time by utilizing a precision strain gauge or stress transducer. The decrease in pressure can come from two sources: (i) the diffusive loss across the wetted filter; since the upstream facet pressure within the holder is constant, it decreases progressively all the while diffusion takes place via the wetted membrane, and (ii) source of strain decay could presumably be a leak of the filter system setup. An essential affect on the measurement of the stress maintain test is the upstream air volume throughout the filter system. This volume has to be determined first to specify the utmost allowable strain drop worth. This strain is recognized as take a look at strain and generally specified at 80% of the bubble level stress. This means a rise in sensitivity of the check, but also a rise of temperature influences, if changes happen. Filter manufacturers specify most allowable stress drop values, using their most allowable and correlated diffusive flow value, and convert this diffusive circulate maximum with the upstream quantity right into a most allowable stress drop. Any temperature change in the course of the test will distort the true outcome as a rise in the temperature will lower the pressure drop, and a decrease will artificially elevate the pressure drop.

Real Experiences: Customer Reviews on Moduretic

Giores, 65 years: A portion of the supposed affected person inhabitants may have tolerability or allergic responses to particular elements typically utilized in a product or formulation.

Thorald, 41 years: The examine ought to be designed to simulate the use of the product in the clinic, including the filling quantity of the container and any dilution/reconstitution earlier than use.

Aschnu, 62 years: Peritoneal fluid ought to turn out to be clear with improvement of peritonitis and erythema, and discharge should remit with improvement of catheter-related infections.

Redge, 31 years: Intensive lipid lowering with atorvastatin in patients with steady coronary disease.

Dawson, 22 years: Process considerations include the processes utilized in cleansing, their stage of automation, the quantity of human intervention, and the potential for variation in all of those considerations.

Inog, 39 years: Although the decrease detection and counting is 2 �m, and ranges to larger, seen particles with circulate cell and objective choice, categorization is possible for particles 5 �m only due to pixelrelated decision limits.

Musan, 35 years: A strategy to reduce the disruptive effects of convection throughout freezing, known as unidirectional freezing, is mentioned under.

Kamak, 52 years: Two case studies are introduced during which cleansing was performed with out regard to the composition and properties of the residue.

10 of 10 - Review by N. Marlo

Votes: 37 votes

Total customer reviews: 37

References

- Goh AC, Goldfarb DW, Sander JC, et al: Global evaluative assessment of robotic skills: validation of a clinical assessment tool to measure robotic surgical skills, J Urol 187(1):247-252, 2012.

- Gomez RG, Castanheira AC, McAninch JW: Gunshot wounds to the male external genitalia, J Urol 150:1147n1149, 1993.

- Moran CA, Suster S, Koss MN. Primary germ cell tumors of the mediastinum: III. Yolk sac tumor, embryonal carcinoma, choriocarcinoma, and combined nonteratomatous germ cell tumors of the mediastinum-a clinicopathologic and immunohistochemical study of 64 cases. Cancer 1997;80(4):699-707.

- Story DA, Ronco C, Bellomo R. Trace element and vitamin concentration and losses in critically ill patients treated with continuous venovenous hemofiltration. Crit Care Med. 1999;27:220-223.

- Kohanpour MA, Sanavi S, Peeri M, et al: Effect of submaximal aerobic exercise in hypoxic conditions on proteinuria and hematuria in physically trained young men, Iran J Kidney Dis 6:192-197, 2012.