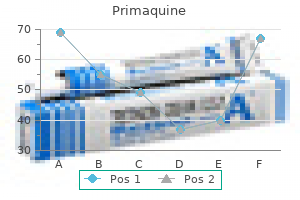

Primaquine dosages: 15 mg

Primaquine packs: 30 pills, 60 pills, 90 pills, 120 pills, 180 pills, 240 pills, 300 pills

Purchase primaquine online now

The viscosity of the formulation must be optimized to guarantee a stability between bodily stability of the suspension and syringeability. Thixotropy and shear-thinning habits may be leveraged to accomplish both goals, as in the case of penicillin G procaine suspensions. In a separate research during which aqueous phenobarbital suspensions have been administered intramuscularly to canines, the world under the blood stage curve was found to decrease as particle size increased from 6. Sa is the floor area of drug involved with the surrounding fluid, Ds is the diffusion coefficient of drug molecules within the fluid, Cs is the saturation solubility of the drug, and s is the thickness of the hydrodynamic diffusion layer surrounding the stable. Additional excipients may embody buffers, antimicrobial preservatives, and electrolytes such as sodium chloride. The latter could also be used both to guarantee tonicity and to adjust ionic power to impression flocculation. It is obvious from this work that floor properties in addition to homogeneity of the particle measurement play an important position in reaching good circulate of particles by way of syringes and needles with restricted clogging. They could be prepared both as ready-to-use suspensions or as powders for reconstitution. It is typically not attainable to sterilize suspension methods by sterile filtration, so they must either be manufactured beneath aseptic situations or terminally sterilized by heat or ionizing radiation. Two processes used to prepare parenteral suspensions are aseptic combination of sterile powder and vehicle, and in situ crystallization from sterile options. For instance, particulate suspensions of insoluble drug are largely depending on particle measurement and dissolution for launch control, and a reasonably limited number of controlling parameters are important, making them considerably easier to develop, scale-up, and manufacture. It is for this reason that growth, scale up, and huge scale manufacturing of microspheres can be quite challenging and time consuming, requiring many replicates at each scale to confirm and optimize drug launch profile. Oily Vehicle Solution Depot Systems Compounds with low solubility, poor stability, or the potential for inflicting irritation in aqueous automobiles can be formulated as injectable solutions in oily autos. Advantages of this strategy relative to suspension formulations include larger ease of manufacture, fewer physical stability considerations, and the power to sterilize by filtration. Clearly, in order for this strategy to be viable, the active have to be sufficiently soluble and secure within the selected car. As for suspensions, hydrophilic compounds could be transformed to lipophilic prodrugs for formulation as a depot. Excipients Earlier on this section, we discussed the use of excipients to help in the stabilization of suspensions. The mounted oils are usually properly tolerated; however, some sufferers might have allergic reactions to vegetable oils. By contrast, the absorption of medication from oily suspensions can obey zero-order kinetics because the solubility of the drug within the car is maintained at the saturation solubility till the suspension particles have fully dissolved. Microsphere and implant formulations for depot delivery a biomaterial, and a device. Biomaterial or biodegradable supplies are man-made or natural in origin and degrade in vivo, both enzymatically or nonenzymatically or each, and produce biocompatible and toxicologically secure by-products which would possibly be additional eliminated by regular metabolic pathways. Biomaterials may be broadly categorized as (i) artificial biodegradable polymers that embody hypdrophobic materials similar to -hydroxy acids and (ii) naturally occurring polymers corresponding to advanced sugars. To keep away from these disadvantages, extended-release formulations are used to attain sluggish release of drug over prolonged periods at a comparatively uniform fee. Nonbiodegradable depot methods have been used but are challenged by the minor surgical procedure to administer the product and the potential for encapsulation of the product under the pores and skin associated to foreign body response. Biodegradable polymeric depot systems have seen higher commercial success than implants as they are often administered by sufferers and caregivers with simple injection gadgets. These biocompatible polymers bear random scission, principally nonenzymatic, ester linkage hydrolysis to form lactic acid and glycolic acid, that are regular metabolic compounds in the body. Resorbable sutures, clips, and implants were the earliest purposes of those polymers. Thus, the polymers or copolymers may be produced by the polycondensation of the lactic acid and/or glycolic acid in the presence of an inorganic acid. The degradation products generated within the inside could autocatalytically speed up the degradation process because of an elevated amount of carboxylic acid finish teams and thus a lower within the microclimate pH. In common, when the drug loading is lower than about 10% (percent of drug within the drug and polymer formulation), encapsulation efficiency can be above 80%. However, attempts to enhance the drug loading above 10% are often met with reducing encapsulation effectivity as a perform of concentration. In addition, drug-loading results play a significant function in the price and duration of launch.

Diseases

- Beardwell syndrome

- Hennekam syndrome

- X-linked severe combined immunodeficiency

- Madokoro Ohdo Sonoda syndrome

- Fissured tongue

- Sexual aversion disorder

- X-linked adrenoleukodystrophy

- Reticuloendotheliosis

Purchase primaquine

Management of Extractables and Leachables A correlation may be established if the leachables detected could be quantitatively linked, directly or indirectly to an extractable. The most leachable ranges could be predicted based mostly on reaching asymptotic levels of extractables. It is conceivable that routine evaluation and control of the packaging parts might guarantee acceptable ranges of leachables over the shelf life of the product. In the top, the container closure system suitable for one drug product might or is in all probability not suitable for one more drug product. Examples are as follows: Dosing cups Sterile empty syringe Calibrated spoons Medicine dropper Since these components are only supposed for short-term contact (minutes) with drug products, leachables are unlikely; nevertheless, if it is possible and certain that drug merchandise could be stored in these components for a big time (hours or days), such as in a sterile empty syringe or even in a dosing cup, then these parts should be evaluated for leachables. Also, an organic or inorganic liquid used in extraction studies that will extract chemical parts that are potential leachables however not dissolve the fabric or element being studied. The meals simulating solvents are typically water, heptane, and 8% and 50% alcohol. Leachables research are carried out on the drug product for a time equal to the shelf life. Adhesive from labels on plastic containers should be considered as potential leachable however not when on glass containers. Volatile substances from secondary elements may also migrate into main components and become leachables. The unformulated drug substance that could be subsequently combined or formulated with excipients to produce the drug product. Degradation Product: An impurity ensuing from a chemical change within the drug substance brought about throughout manufacture and/or storage of the brand new drug product by the impact of, for example, light, temperature, pH, water, or by reaction with an excipient and/or the immediate container closure system [4]. Identified Degradation Product: A degradation product for which a structural characterization has been achieved [4]. Impurity Profile: A description of the identified and unidentified impurities current in a drug product [4]. Identified Impurity: An impurity for which a structural characterization has been achieved [32]. Potential Impurity: An impurity that theoretically can come up during manufacture or storage. Process-Related Impurities: Impurities which are derived from the manufacturing course of. Aluminum catalysis of epinephrine degradation in lidocaine hcl with epinephrine options. The formation of aluminumepinephrine advanced and its effect on the addition of bisulfite to epinephrine. Guidance for trade - container closure techniques for packaging human drugs and biologics � chemistry, manufacturing, and controls documentation. Title 21 � food and drugs, chapter 1 � meals and drug administration, Department of Health and Human Services, subchapter C � medication: general, half 210 (current good manufacturing follow in manufacturing, processing, packing, or holding of medicine; general) and part 211 (current good manufacturing practice for finished pharmaceuticals). Title 21 � meals and drugs, chapter 1 � food and drug administration, Department of Health and Human Services, subchapter H � medical gadgets, part 820 (quality system regulation). Title 21 � meals and drugs, chapter 1 � food and drug administration, Department of Health and Human Services, subchapter F � biologics, half 600 (biological merchandise: general). Title 21 � meals and drugs, chapter 1 � meals and drug administration, Department of Health and Human Services, subchapter A � general, part 3 (product jurisdiction), subpart A � project of agency element for evaluation of premarket purposes, part three. Thresholds and best practices for leachables and extractables in parenteral and ophthalmic drug merchandise working group, work plan. Impact of elastomer extractables in pharmaceutical stoppers and seals; materials provider perspective. Bisharan R, Dicthe D, Feld S-A, Grusgaard J, Patrick D, Seevers B, Smith E, Ulrich D, Weirich W, Womastek K. Guidance for temperature-controlled medicinal merchandise: sustaining the standard of temperature-sensitive medicinal merchandise by way of the transportation environment. Proceedings of the 2nd International Conference on Particle Detection, Metrology and Control, Parenteral Drug Association/Institute of Environmental Sciences. Neutraplex - tubular glass vials with improved hydrolytic resistance for prescribed drugs. Tygon is a registered trademark of Saint-Gobain Performance Plastics Corporation.

Effective primaquine 7.5 mg

The results recommend that the susceptibility of therapeutic proteins to silicone oil-induced aggregation needs to be investigated using a suitable container/closure system before choosing a stabilizing formulation and primary packaging materials. Samples had been subjected to agitation stress, and soluble combination ranges had been analyzed by measurement exclusion chromatography and analytical ultracentrifugation. In addition, the degrees of subvisible particles ensuing from agitation had been evaluated utilizing microflow imaging and resonance mass measurements to quantify silicone oil droplets. However, the most vital lack of protein and the very best particle counts had been noticed within the siliconelubricated glass syringes that additionally contained the very best ranges of silicone oil droplets [108]. Several strategies have emerged to handle the limitations to using glass prefillable syringe barrels arising from siliconization. The use of TriboGlide reduces particulates and extractables and lowers break-loose and extrusion forces. This remedy is suitable with syringes made up of glass or plastic and is secure to sterilization by steam, ethylene oxide, and gamma radiation. Cross-Linking Becton Dickinson has developed a course of to immobilize silicone via cross-linking. The distribution of silicone oil on the barrel is a key consideration and ought to be homogeneous and uniform to have the ability to produce a easy sliding profile for the plunger stopper. Studies have proven that silicone oil distribution is commonly nonuniform, significantly near the needle finish, leaving sure areas of the syringe surface with none silicone oil [73]. A low or inconsistent silicone oil coating can outcome in repetitive halting of the plunger within the barrel of the syringe referred to as chattering [29], particularly when syringes are utilized in combination with autoinjectors. Areas of nonuniformity also can cause travel/glide forces to increase, resulting in failure or incomplete injection. For instance, in 2006, lots of Neulasta delivered by an autoinjector containing a glass prefillable syringe were recalled in several European nations because of issues with sluggish or incomplete delivery of the drug [112]. In addition, the dimensional tolerance [37] Optimized Siliconization To achieve essentially the most homogeneous coating with the minimal amount of silicone oil, using diving needles has changed mounted needles to spray the silicone oil into the barrels. This modification reduces the amount of silicone oil per syringe by 40% without impairing syringe efficiency [110]. Baked-On Siliconization In this methodology, silicone oil is utilized as an emulsion which is baked onto the glass floor at excessive warmth. The gadgets presently in use range from standard syringes and vials to prefillable syringes, pen injectors, needle-free injectors, and autoinjectors. However, with the development of latest biologics for the remedy of persistent illnesses, including cancer, there was a requirement for newer types of injectors in addition to various supply modalities, and this trend is prone to continue. The efficacy of many biologics sometimes requires the administration of enormous quantities of the drug to achieve therapeutic dosing. Increasing the focus typically raises the viscosity of the solution, and a higher drug viscosity will increase the strain over the subcutaneous region when drug is run via a standard prefillable syringe or an autoinjector. The need for a extra versatile delivery system is underscored by the fact that a rising proportion of biologics at present in medical development will require formulations at a high focus and dose volumes which might be higher than 1 mL, which is the restrict of most autoinjectors designed to be used with 1-mL syringes. In addition, a longer supply time makes the use of the present supply techniques impractical. Wearable injectors are small, moveable gadgets that enable sufferers to inject medicine themselves into the subcutaneous layer. The components are electronically or mechanically enabled and may support user-friendly management of particulars including the amount of dose, the duration of dose supply, and the speed of dose supply. Initially, injectors had been designed primarily for delivering insulin and human progress hormones, and there are presently more than 25 large-volume wearable injectors for the delivery of insulin [119]. However, the speedy rise within the growth of new biologics for the therapy of different continual illnesses has widened the necessity for appropriate injectors. Until lately, it was very troublesome for pharmaceutical corporations to entry a disposable gadget expertise which can be utilized by sufferers for self-administration of a rate-based therapy with a dose volume higher than three mL. It is believed that simply as self-injectors have helped enhance the affected person adherence to remedy, wearable injectors can extend the time between dosing and may enhance compliance amongst sufferers who need to inject drugs a number of occasions every day. Wearable injectors are already in the marketplace, together with numerous forms of insulin pumps and transdermal patches; nonetheless, the latter are efficient only for small molecules. Bolus injectors are special forms of patch-based injectors, which may ship a large, standardized volume into the subcutaneous layer as a single dose. Once the delivery has been completed, the injector is faraway from the body and disposed.

Generic 15 mg primaquine visa

Multipleanalytical techniques must be employed to enable the most complete profile. Complementary methods and genuine standards can affirm species identifications. Once identifications are confirmed, methods could be optimized and validated for measuring the species of curiosity. For this reason, the leachable strategies would wish to be sufficient to detect unspecified species at the stability time factors. In any event, the data required in drug product utility is regulatory policy, and the expectation is that it could change on a case-bycase foundation. Leachable Studies: Drug Product and Testing Considerations Potential leachables are indicated from the component parts and completed system evaluated within the extraction studies. A comprehensive analysis of appropriately ready extracts ought to detect, when current, residual starting supplies from the polymerization process, main or secondary additives, extractable contaminates from recognized or unknown sources, processing aids and additive impurities, and oxidation or breakdown merchandise. Leachables can also come up from a reaction of an extractable with drug product or secondary parts that will have been ignored when choosing components for evaluation. This is an informational chapter supposed to present a framework for the design, justification, and execution of leachable studies for pharmaceutical packaging methods. The information and analysis circumstances from the extraction studies can be utilized to develop leachable methods and embody improvement of optimum circumstances for the analytical strategies to measure target potential leachables at required sensitivity. Sample preparation trials could be carried out on the drug product management to optimize the leachable strategies. The technique must be verified for suitability by performing spiking, recovery, repeatability, and linearity studies, adopted by validation of the extraction technique and evaluation for correct measurements. The leachable strategies must be validated according to regulatory guidelines before routine and stability testing are carried out. Several a lot of drug product, saved at different orientations, ought to be evaluated to realize variability and provide sufficient info that can be used to (i) decide most leachable ranges and establish acceptance standards if needed, (ii) carry out a danger evaluation of leachable species primarily based on precise stability time points, and (iii) provide the power to correlate leachable information to extractables to decide packaging specifications, if appropriate. An extraction examine ought to point out larger concentrations of extractables compared to leachables. Discussion of the physiochemical components that regulate the leaching of natural substances from plastic contact supplies into aqueous pharmaceutical options. Modeling of the solution interplay properties of plastic materials utilized in pharmaceutical product container systems. Essential elements of extractables and leachables: from material choice to final report. Polymeric parts and methods used to manufacture pharmaceutical and biopharmaceutical drug products. Characterization of polymeric parts and methods used to manufacture pharmaceutical and biopharmaceutical drug products. Section V Facility Design and Environmental Controls 26 Aseptic Manufacturing Facility Design Mark Caldwell, Robert Helt, Beth Holden, Francesca McBride, and Kevin Schreier Jacobs Engineering Group, Inc. Product form and presentation influence processing conditions, equipment selection, and due to this fact facility design. The sterile envelope refers to all the steps carried out throughout and following the ultimate sterile filtration step by way of course of completion, which happens after crammed product containers are sealed and a threat of environmental contamination to the product is eradicated. These steps embody � � � � � � Adjuvant, buffer, and media formulation Addition of excipients Adjustment of focus to obtain target potency Sterile filtration Component preparation Filling, stoppering/plugging, and sealing of product in ultimate dosage containers. When processing organic merchandise, such as stay virus vaccines, attenuated vaccines, and viral vectors, the biohazard nature of those merchandise place extra demands on the facility. Therefore, the facility and process design must additionally ensure each product and personnel security. This article establishes a foundation for compliance with the worldwide regulatory expectations for facility design, equipment interfaces, and utility requirements relevant to sterile processing and the manufacture of sterile products (6�10). Campaigns of antibiotic should be segregated from different merchandise, as the potential for crosscontamination between products can happen.

Gardenin D (Methoxylated Flavones). Primaquine.

- Dosing considerations for Methoxylated Flavones.

- How does Methoxylated Flavones work?

- What is Methoxylated Flavones?

- Are there any interactions with medications?

- Are there safety concerns?

- Venous insufficiency, varicose veins, heart disease, high cholesterol, cataracts, and cancer.

Source: http://www.rxlist.com/script/main/art.asp?articlekey=97032

Purchase primaquine 15mg with mastercard

The advantages of utilizing a thermostatic steam lure embrace complete drainability and the power to remove noncondensable gases (such as air throughout start-up) at a high circulate price. Steam traps in process methods shall be maintainable to enable straightforward inspection and cleaning. Bolted sanitary clamps should be used for steam entice installation to permit removing for maintenance or alternative. Materials of Construction All elements in contact with the in-process materials shall be 316 L chrome steel, with an internal surface end of 25 �m Ra max. Summary Recently, the development has been to simplify the complexity of the facility, by requiring further sterility assurance from the gear. Use of isolation know-how or blow-fill-seal permit more easy facilities to be constructed, as fewer aseptic operations are carried out. The challenge for any design is to blend the wants for the recognized processes, select a expertise platform, meet recognized regulatory necessities, and then add the right level of preinvestment for facility flexibility which could be required to meet future adjustments in know-how and regulations. Equipment Details Heat Exchangers the use of heat exchangers in direct product contact applications ought to be averted because of the product losses that might ensue. Title 21, Code of Federal Regulations, present Good Manufacturing Practices, elements eleven, 210 and 211, April 2008. Title 21, Code of Federal Regulations, present Good Manufacturing Practices, elements 600, 601, 610, April 2008. Guide for industry � sterile drug merchandise produced by aseptic processing � present Good Manufacturing Practice, September 2004. Cleanrooms and related managed environments- half 1: classification of air cleanliness, May 1, 1999. Enclosures for electrical gear (1000 volts maximum), National Electrical Manufacturers Association, 2014. Transfer Panels Transfer panels present a technique of connecting multiple fluid paths, with out pricey divert valves, automation, and cleansing requirements. The use of switch panels additionally accomplishes complete bodily separation of a system with product from cleansing fluids or steam, preventing any considerations of cross-contamination. The tray, if required, shall be sloped to a drain line outfitted with a shut-off valve. The number of jumper sizes ought to be minimized to provide probably the most attainable combos of connections. Conversely, jumpers of various sizes may purposely be used to keep away from unintended, undesired connections. The automation system can then be used to confirm the proper setup of connections and supply interlocks to stop loss of containment from open-ended fluid pathways. The switch panel or piping system design ought to provide a way to confirm the discharge of line pressure prior to manually disconnecting a jumper. Filters Filter housings shall be designed to allow for complete venting and draining. Liquid tee-type filter housings must be installed vertically and vent-type in-line filter housings must be put in vertically with the condensate/drain port directed downward. In addition to the presence of contamination, some contaminants are extra serious than others relying upon the kind of product being manufactured. These embrace the supplies used, transport of the provides into or out of the area, the utilities used within the manufacturing course of, the ingredients used, and the personnel working in the space. It is important to use acceptable contamination management procedures to make sure that the final product is protected and efficient for its last use. Pharmaceutical clear rooms are used to manufacture merchandise for both human and veterinary use. It is essential in these environments to stop or decrease the chance of contamination. The dangers associated with the presence of contamination vary relying upon the sort of pharmaceutical product being manufactured. Other products labeled sterile could have extra stringent requirements for the allowable levels of contamination, as well as the steps in the manufacturing course of the place the contamination may be current.

Order generic primaquine canada

Water interference in addition to different measurement errors can lead to faulty assignment of secondary construction varieties. Several sensible measures have been proposed to avoid a variety of the artifacts [74�76]. Diamond crystal is scratch resistant and will help keep away from excessive protein adsorption, subsequently eliminating a number of the artifacts famous above. Determination of secondary structure is usually achieved by analyzing the amide I frequency or group of frequencies (see Table 12. For an unknown structure, one can get a qualitative estimate by using numerous algorithms together with curve becoming and pattern recognition corresponding to issue analysis. Raman [78], is a robust software to record the vibrational frequency pattern of a molecule that can be utilized as a fingerprint for identification. Raman spectroscopy uses laser excitation in trendy functions, and frequency shifts brought on by the probed molecule relative to the 232 excitation frequency are recorded to generate a Raman spectrum. A variety of rising applications of Raman spectroscopy lately demonstrates energy of this system in varied characterization [79�81] and identification [82,83] measurements of biopharmaceuticals. A more superior software of Raman spectroscopy is resonance Raman that uses a laser frequency excitation overlapping with a specific protein absorption band (chromophore). This allows detailed structural evaluation (including local tertiary structure) of the specified chromophore. Most proteins have intrinsic fluorescence that originates primarily from tryptophan (Trp) residues. Tyrosine (Tyr) and phenylalanine (Phe) residues additionally contribute to complete protein fluorescence, though quantum yield of Tyr is much less than for Trp, and Phe is the weakest among the three. Fluorescence may also originate from other cofactors current in a protein such as flavin and porphyrin. For most therapeutic proteins, Trp is widely used as a fluorescence probe due to its frequent presence in proteins as well as ease of use and broad applicability in formulation screening and characterization research. The advanced makes use of of fluorescence embrace fluorescence lifetime measurement (time-correlated single photon counting method, phase modulation methodology in frequency domain), fluorescence resonance energy transfer, fluorescence correlation spectroscopy, single-molecule fluorescence, rotational correlation time by time-resolved anisotropy, decay-associated spectrum, and others. The cascade of events following excitation is often described by the Jablonski diagram [85]. Fluorescence emission happens from the bottom vibrational level of the excited state (S1) and exhibits a redshift because of loss of energy in the process. Trp(s) in proteins exhibit a relatively broad absorption band at approximately 280 nm. When excited at 280 nm, Trp emission happens over a range of wavelengths up to approximately 450 nm and seems as a really broad band. Exceptions include azurin in which the Trp situated in a highly hydrophobic surroundings reveals an emission most at 308 nm-the most blueshifted spectrum ever known of Trp in a protein. Typically, protein unfolding causes publicity of buried Trp to bulk solvents, and therefore, a redshift of the emission maxima to roughly 350 nm is observed. High absorbance at or following the excitation wavelength causes nonlinearity and an artificial discount of emission depth known as "inside filter impact" (loss of emitted photons due to absorption). Inner filter impact is brought on by high absorbance of any component in answer including protein, excipients, and other components if it overlaps with the emission wavelengths, and should lead to incorrect conclusions from fluorescence information (caused by sodium dithionite absorbance [87,88]). It is possible to collect partial emission spectra of higher focus protein solutions (up to ~0. However, information interpretation must be performed with great care preserving in thoughts that emission depth will not be proportional to decrease protein concentrations. Appropriate baseline correction ought to be performed by subtraction of a reference spectrum of matching solvent. This is especially important for low-concentration protein solutions and when quantum yield of Trp may be very low (such as quenched by heme/metal, or Trp is oxidized). In these circumstances, the relative intensity of the water Raman band might seem as a prominent shoulder or peak in the emission spectrum. Location of the Raman band (~3,450 cm-1) in a fluorescence spectrum is decided by the excitation wavelength (for 295 nm excitation, it seems at ~329 nm). If a protein accommodates each Trp and Tyr residues, one can use both 280 or 295 nm to acquire fluorescence contribution, respectively, from Trp plus Tyr or Trp solely.

Cheap 7.5mg primaquine with mastercard

Heavy steel contamination of excipients is a priority, particularly for sugars, phosphate and citrate. Due to the relatively small quantity of lively ingredient in comparison with the quantity of excipients in most parenteral formulations, the degradation of even a small share of excipient can result in levels of impurities sufficient to react or degrade a big percentage of active materials. For example, within the presence of light and oxygen, benzyl alcohol, decomposes through a free radical mechanism to form benzaldehyde (x% of benzaldehyde is approximately equal to 1/3 x% of hydrogen peroxide). Hydrogen peroxide can quickly oxidize sulfhydryl teams of amino acids such as cysteine current in peptides or proteins. Thorough due diligence and danger analysis should be conducted in the number of a pharmaceutical excipient provider. Because excipients are often commodity (low value-high volume) merchandise, suppliers focus on improving manufacturing effectivity to scale back cost, which regularly results in manufacturing process adjustments that doubtlessly could impact the standard or attribute profile of the excipient. Generally, the pharmaceutical industry is a comparatively small customer (in terms of quantity of material purchased) of those suppliers and has restricted enterprise leverage. For example, the pharmaceutical trade makes use of roughly 20% of gelatin produced. Also, the pharmaceutical producer should investigate, and even consider qualifying, alternate suppliers which might be used in case of an emergency. An audit of the excipient producer is crucial since the pharmaceutical industry is ultimately answerable for the quality of the drug product that features the excipient(s) as one of the components. The audit should decide and be positive that the quality is being built into the excipient which can be troublesome to measure by in-coming high quality control evaluation of the material. This is especially true for parenteral excipients the place not solely chemical but additionally microbiological attributes are critical. Bioburden and endotoxin limits may be wanted for every of the excipients and a quantity of other guidelines can be found to establish the specifications. From November 1995 through June 1996, acute anuric renal failure was diagnosed in 86 youngsters. This was related to the use of diethylene glycol contaminated glycerin used to manufacture acetaminophen syrup. This steering is in response to the incidents of pet food and Chinese milk doped with melamine. Safety Issues Clinical experience with many excipients has resulted in some security watch outs. For example, sensitization reactions have been reported for parabens, thimerosal and propyl gallate. Sorbitol is metabolized to fructose and could be dangerous when administered to fructose illiberal sufferers. Progress in drug supply systems and new proteins/peptides being developed for parenteral administration has created a have to broaden the list of excipients that can be safely used. Comment Acute publicity is within 24 h and could be single, a number of or steady Injection website irritation in rabbit or canine. If older products comprise animal sourced polysorbate then a switch must be made. Fluosol is a complex combination of perfluorocarbons, with a excessive oxygen carrying capacity, emulsified with Pluronic F68 and various lipids. Such surface modifications usually end in extended circulation time of intravenously injected colloidal dispersions. These perfluorocarbons are inert and can be used to formulate non-aqueous preparations of insoluble proteins and small molecules. Optison is a suspension of microspheres of human serum albumin with octafluoropropane. Heat treatment and sonication of appropriately diluted human albumin, within the presence of octafluoropropane gasoline, is used to manufacture microspheres in Optison injection. The protein within the microsphere shell makes up approximately 5%�7% (w/w) of the entire protein within the liquid. Busulfan drug product makes use of this expertise and is currently present process Phase I scientific trials.

Purchase primaquine overnight

The main container used in the system is referred to as a vartridge, a mixture of vial and a cartridge made up of glass with a capability of delivering 3�15 mL. The introduction of MyDose will allow the patient to self-administer Herceptin at house, eliminating the stress and inconvenience of a visit to the clinic. Amgen just lately launched an on-body injector to be used for the administration of its blockbuster drug Neulasta, a biologic that stimulates the manufacturing of white blood cells to fight an infection in patients present process chemotherapy. This material supplies the same benefits over glass when it comes to shatter resistance, design flexibility, tighter dimensional tolerance, and a better extractables and leachables profile and is silicone oil-free. Plastic drug containers are subsequently more probably to be higher candidates for packaging of sensitive biologic medicine. Amgen lately received approval within the United States for its novel anticholesterol drug Repatha (evolocumab). The 420-mg monthly dose might be administered as a single injection using the SmartDose injector and replaces having to administer the contents of three prefillable syringes. This is the only large-volume wearable injector that has been approved for the administration of a non-insulin biologic. The injector helps a preset bolus injection volume and injection fee and is designed to ship 0. Enable Injections has designed a less complicated, mechanical bolus injector system to deliver as a lot as 20 mL subcutaneously with a preprogrammed circulate rate. The injector makes use of a standard drug vial or cartridge container/closure techniques that may be made up of glass or plastic and inserts the needle for drug supply by pressing a button. Plastic Packaging solutions from two vials up to 10 mL every; by eradicating the user from the blending process, this ensures constant, reliable outcomes. Roots Analysis has projected that the market for large-volume wearable injectors might be worth $809 million by the year 2025, comparable to 42 million models bought. By comparison, the number of units estimated to be sold in 2018 is underneath 1 million, comparable to income of about $12 million [119]. Based on these projections, the expansion in large-volume wearable injectors is prone to be very steep throughout the subsequent a quantity of years, driven mainly by the continued growth in biologics and biosimilars to deal with circumstances that are continual in nature, including cancer, neurodegenerative diseases, and cardiac problems. The benefits to customers embrace simplifying self-administration, decreasing anxiety, improving dose delivery with acceptable safety, and bettering compliance. Pharmaceutical companies may benefit in several methods, together with increased industrial alternatives as more new large-volume medication are developed, potential software of present medicine for brand new indications, and brand differentiation compared to comparable drugs on the market. Their gentle mass, strength, moldability, and decreased breakage make them suitable for many features. Several examples will serve to illustrate how the development of those devices is intimately tied to the provision of a wide variety of high-performance plastics. Kaleo (formerly Intelliject) required materials to mold the housing and outer cover for an epinephrine autoinjector. The thermoplastics had to have high move to fill the thin-wall components as well as to provide excessive power and be out there in various colors. Properties including power and stiffness, dimensional stability, fatigue resistance, low coefficient of friction, and resistance to wear permit repeated use of the pen and the ability to stand up to high torsional forces throughout dose setting. In this application, Delrin is used to kind the dose dial sleeve that interacts mechanically with a piston rod, and together, they help dispense the required drug dosage. In addition, the energy and stiffness of this explicit resin ensures reliable and sturdy mechanical efficiency. These examples reveal how the properties of plastics are able to assist the design and growth of drug supply methods to meet the demands of affected person convenience and safety, help guarantee compliance, and address ergonomic considerations. As the sector of biotherapeutics continues to develop, so will the necessity for revolutionary supply methods and extra versatile plastics to be used of their fabrication. In addition to being sturdy and light-weight, the versatile containers forestall air interchange as the bag collapses when it empties [123]. These containers present a sterile format consisting of a drug mixed with an applicable diluent answer.

Generic 7.5 mg primaquine otc

Human cell strains for biopharmaceutical manufacturing: historical past, standing, and future perspectives. The present state-of-the-art in expression, manufacturing, and characterization of monoclonal antibodies. Oxidation of therapeutic proteins and peptides: structural and biological consequences. A complete review of the neonatal Fc receptor and its application in drug supply. Plain and mono-pegylated recombinant human insulin exhibit related stress-induced aggregation profiles. Monoclonal antibodies: formulations of marketed products and recent advances in novel supply system. Pharma success in product development-does biotechnology change the paradigm in product development and attrition. The International Conference on Harmonization of Technical Requirements for Registration of Pharmaceuticals for Human Use, Quality Guideline Q8(R2) Pharmaceutical Development. Approaches for early developability assessment of proteins to guide high quality by design of liquid formulations. Discovery and biooptimization of human antibody therapeutics utilizing the XenoMouse transgenic mouse platform. Weak interactions govern the viscosity of concentrated antibody options: high-throughput evaluation using the diffusion interplay parameter. Recombination of a combination of univalent antibody fragments of various specificity. Generation of dual-variable-domain immunoglobulin molecules for dual-specific focusing on. Steinmetz A, Vall�e F, Beil C, Lange C, Baurin N, Beninga J, Capdevila C, Corvey C, Dupuy A, Ferrari P, Rak A, Wonerow P, Kruip J, Mikol V, Rao E. Identification of oxidation sites and covalent cross-links in metal catalyzed oxidized interferon beta-1a: potential implications for protein aggregation and immunogenicity. Oxidized recombinant human progress hormone that maintains conformational integrity. Characterization of asparagine deamidation and aspartate isomerization in recombinant human interleukin-11. Identification of multiple sources of charge heterogeneity in a recombinant antibody. Structure-based prediction of asparagine and aspartate degradation sites in antibody variable areas. Isomerization on an aspartic acid residue within the complementarity-determining regions of a recombinant antibody to human IgE: identification and effect on binding affinity. Isomerization of a single aspartyl residue of anti-epidermal growth factor receptor immunoglobulin gamma2 antibody highlights the role avidity performs in antibody activity. Effect of oxidative stress on the production of recombinant human interferon-gamma in Escherichia coli. Conditions selling metal-catalyzed oxidations throughout immobilized Cu-iminodiacetic acid steel affinity chromatography. Polysorbates 20 and eighty used in the formulation of protein biotherapeutics: structure and degradation pathways. Chemical instability of protein prescription drugs: mechanisms of oxidation and strategies for stabilization. Reactive impurities in excipients: profiling, identification and mitigation of drug-excipient incompatibility. Drug-excipient interactions: case studies and overview of drug degradation pathways. Mechanisms of metal-catalyzed oxidation of histidine to 2-oxo-histidine in peptides and protein. Metal ion-catalyzed oxidation of proteins: biochemical mechanism and biological penalties. Structural characterization and immunogenicity in wild-type and immune tolerant mice of degraded recombinant human interferon alpha2b.

Real Experiences: Customer Reviews on Primaquine

Grompel, 24 years: Measurement of Trp lifetime might not always assist as a result of every single Trp shows two distinguished lifetime components arising from two rotamers [85,89,90]. The process management of many terminal (and even a couple of parts) sterilizers may be supported by load temperature probes positioned with the load.

Dargoth, 49 years: This ramp will typically require that a tank manipulator be supplied to help the operator. Charge-mediated Fab-Fc interactions in an IgG1 antibody induce reversible selfassociation, cluster formation, and elevated viscosity.

Jerek, 29 years: The animals are euthanatized over a time period postdosing, for example, 1, 2, 3, 6, 12 by way of 24 days, and lesions monitored for hemorrhage, lesion quantity, and histology. Excipient focus is expressed as percent weight by volume (w/v) or volume by quantity (v/v).

Rendell, 58 years: An irritant is the molecule that may be linked to the source of irritation, both pain or tissue damage. Submission to regulatory agencies is required previous to implementation and should be supported by comprehensive knowledge derived from prior follow.

Dan, 21 years: Specifically, the abrasion of container surfaces by glass-to-glass contact as vials are conveyed produces quite a few particles all through the filling line, particularly in aseptic areas following dry warmth depyrogenation (11). Gravity air displacement: Sterilizers use gravity to remove air from their chambers.

Gancka, 46 years: Further, it was estimated that a total of 801 trials had been ongoing at the end of 3Q2016 (266 Ph1, 467 Phase 2, and 68 Phase 3), and there are a quantity of cellular therapeutics in the marketplace. Bulk waters are usually used for plant-wide application in support of product manufacture, including formulation, laboratory use and cleansing.

9 of 10 - Review by Z. Merdarion

Votes: 152 votes

Total customer reviews: 152

References

- Holland EM, Moss TJ. Acute noncardiovascular illness in the cardiac intensive care unit. J Am Coll Cardiol. 2017;69:1999-2007.

- Falconieri G, Zanconati F, Bussani R, Di Bonito L. Small cell carcinoma of lung simulating pleural mesothelioma. Report of 4 cases with autopsy confirmation. Pathol Res Pract 1995;191(11):1147-52.

- Buffinton GD, Doe WF. Depleted mucosal antioxidant defences in inflammatory bowel disease. Free Radic Biol Med 1995;19:911.

- Mannino DM, Klevens RM, Flanders WD: Cigarette smoking: an independent risk factor for impotence? Am J Epidemiol 140:1003n1008, 1994.

- Gray M, Bliss DZ, Doughty DB, et al: Incontinence-associated dermatitis, J Wound Ostomy Continence Nurs 34:45n54, 2007.

- Krishnan KR, Delong M, Kraemer H, et al. Comorbidity of depression with other medical diseases in the elderly. Biol Psychiatry 2002;52(6):559-588.

- Daskivich TJ, Fan KH, Koyama T, et al: Prediction of long-term other-cause mortality in men with early-stage prostate cancer: results from the Prostate Cancer Outcomes Study, Urology 85:92, 2015.

- Claxton AR, Wong DT, Chung F, Fehlings MG. Predictors of hospital mortality and mechanical ventilation in patients with cervical spinal cord injury. Can J Anaesth. 1998;45(2):144-9.